Take a virtual tour of the facilities in the Centre for Energy Materials Research

https://my.matterport.com/show/?m=SLsiYyUZdQw

Electrochemical storage device research groups

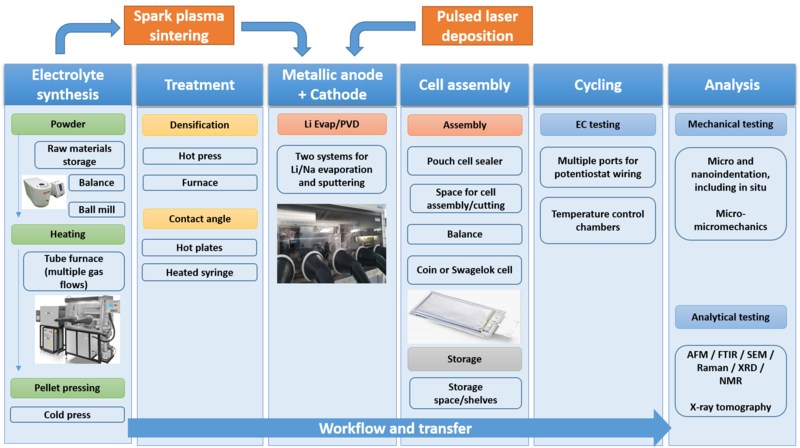

The Royce equipment in the Department of Materials at the University of Oxford is used by a number of research groups working on electrochemical energy storage devices.

The following links highlight key areas of research by these groups.

Peter Bruce's research group

Mauro Pasta's research group

Patrick Grant's Processing of Advanced Materials Group

Robert Weatherup

Chris Grovenor

Robert House

The Faraday Institution

In support of The Faraday Institution’s energy storage research priorities, the Royce has provided state-of-the-art equipment to several Faraday Institution university research teams, including those at Oxford, Sheffield, Manchester, and Cambridge. In this way, the Royce Institute and the Faraday Institution are working together to develop the next generation of energy storage solutions to benefit the UK.

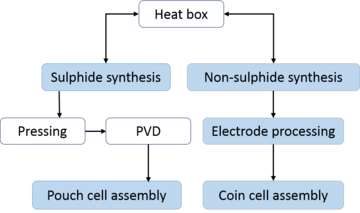

Led by researchers at the University of Oxford, two of the current Faraday Institution projects benefit from the facilities and advanced equipment funded through the Royce.

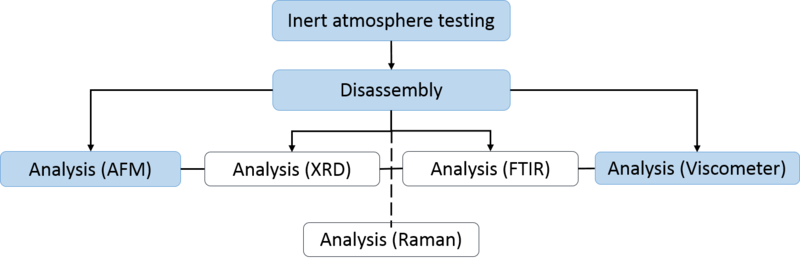

SOLBAT project

Nextrode project

These projects include a number of industrial partners and they form part of a wider program supported by the Faraday Institution.

Some equipment marked ^ was not funded through a Royce capital equipment grant.