Capabilities

Royce equipment and facilities across the Department of Materials at the University of Oxford

Royce facilities are hosted in numerous research groups across the Department of Materials at the University of Oxford.

The equipment associated with the investigation of air-sensitive battery materials is hosted by research groups in the Rex Richards building. These capabilities are shown in more detail on the electrochemical energy storage pages.

Advanced battery electrode fabrication and test equipment are housed at the Begbroke Science Park, in the Advanced Processing Laboratory.

Begbroke is also the home of the Oxford Materials Characterisation Service.

The David Cockayne Centre for Electron Microscopy is home to a wide range of state-of-the-art sample preparation and characterisation tools. The center includes workflows for handling air-sensitive materials.

The facilities in the superconductor and quantum materials research groups include patterning and deposition capabilities.

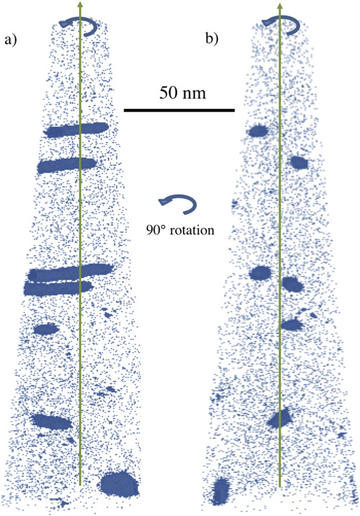

The atom probe tomography group is host to three atom probes, which can reveal sample composition in exquisite detail.

Research capabilities

The David Cockayne Centre for Electron Microscopy (DCCEM) has a dedicated staff of research support scientists and technical support staff. The center offers services to industry, develops new techniques to improve understanding, provides

training, and aims to help researchers obtain the highest possible quality data from the instruments.

Highlights of the DCCEM

- FIB sections and nanomill, for preparation of TEM samples with extremely low beam energies

- SIMS for elemental profiles

- Imaging of light elements in S/TEM with 4D canvas

- Testing mechanical properties of individual grains

- Workflow for the handling of air-sensitive materials

For more details about the equipment and team, please visit https://www-em.materials.ox.ac.uk

Take a 360 degree tour of the David Cockayne Centre for Electron Microscopy at Oxford

https://my.matterport.com/show/?m=96AzAiQNawrThe following Meet the researcher videos offer an introduction to key techniques and instruments

The Oxford Materials Characterisation Service (OMCS) offers materials characterisation and analysis, training, and support. Training can enable booked access to key equipment on an hourly or daily basis, where appropriate.

Highlights

- Surface analysis

- Particle size determination

- Example work is undertaken for electrochemical energy storage devices

- Weld analysis and qualification

- Cell composition

- Investigation of photonic and microelectronic device assemblies

- Forensic analysis

For more details about the capabilities and team, please visit https://www-omcs.materials.ox.ac.uk

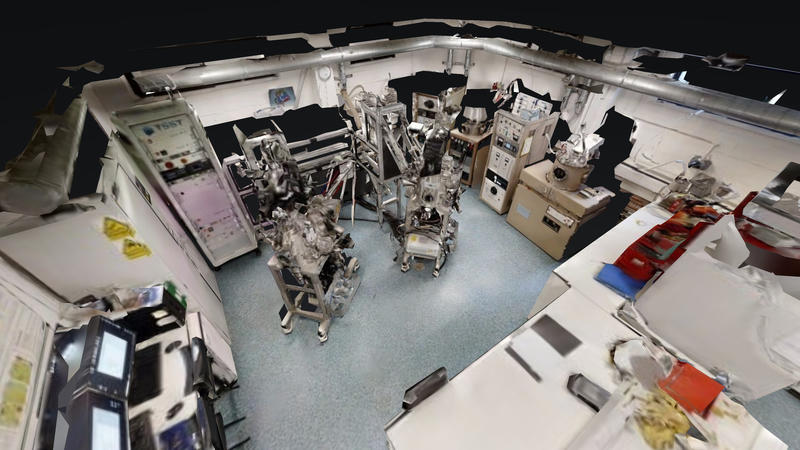

Take a 360 degree tour of the Atom Probe Tomography facilities at Oxford

https://my.matterport.com/show/?m=aFjbVD3ZAuSFor more details about atom probe tomography, please visit https://atomprobe.materials.ox.ac.uk

Applied superconductivity

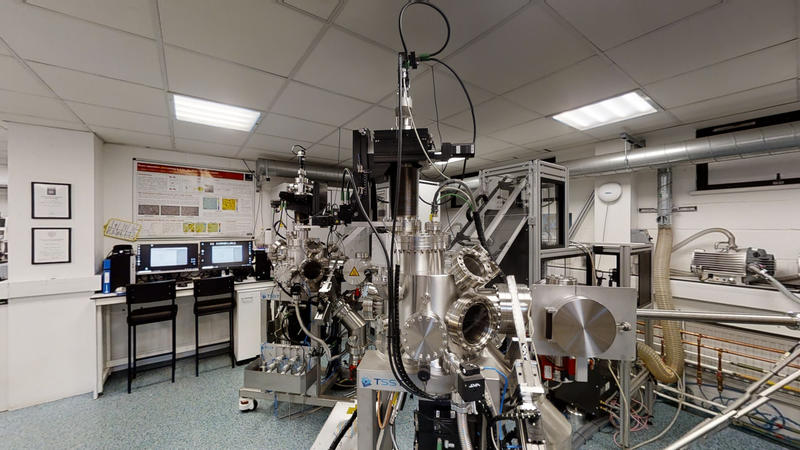

The Centre for Applied Superconductivity at Oxford includes a pulsed laser deposition chamber with load-lock. This Royce-funded equipment complements new experimental facilities, to address identified industry needs.

The deposition chamber sits alongside an Empyrean X-Ray Diffractometer^, for analysis of powder and textures, and an Attocube magnetic force microscope^.

Please take a look at a few photos of Centre for Applied Superconductivity facilities at Oxford

For more details, please visit https://www.cfas.ox.ac.uk/

Quantum technologies

Research into nanomaterials and quantum effects is undertaken using deposition in a Plassys MEDB550S electron beam evaporator, and patterning with a reactive ion etch (Oxford Instruments PlasmaPro 80 Cobra) and electron beam lithography (EOL JBX-5500FS EBL).

Further details

Please use the links to explore further details of the equipment and facilities on offer - and for more on the research activities of groups. ^ Some equipment was not funded through a Royce grant.

A wider range of capabilities and expertise can be accessed through Royce partners. The partners' major Royce-supported equipment and facilities are listed here.